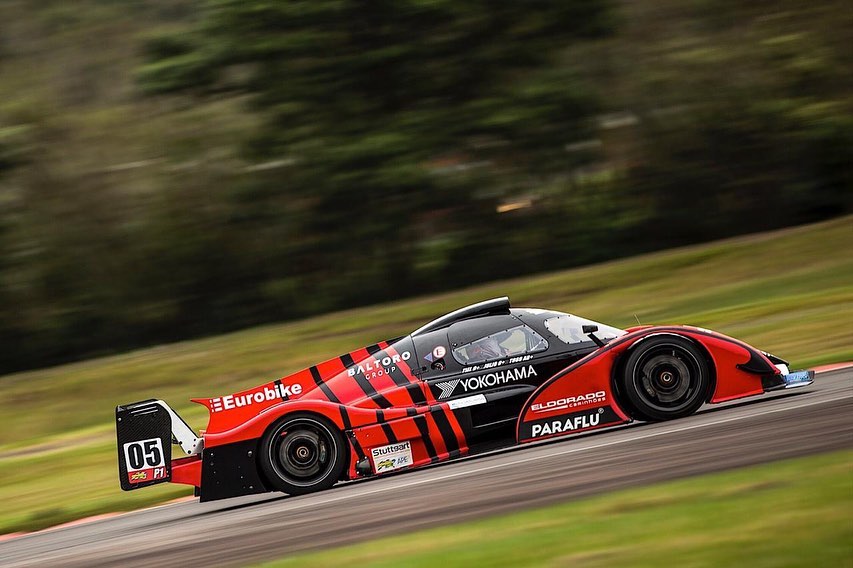

Launched in 2017, the AJR immediately caught attention in the Brazilian motorsport scenario. Project began in 2015, under the management of engineer Silue Gossling, Juliano Moro and Enzo Brocker. Initially thought to be an evolution of the MR18 prototype, with more downforce and a few LMP2 parts, the project grew. Seeking a new rear wing, a completely new bodywork was suggested as being far more effective, which then led to the development of a new 4130 steel tube frame chassis, to give more freedom for the aerodynamic project developed by British company Dynamic Flow Solutions. Another important concept was to create a chassis that allowed different types of powertrain to be mounted, giving freedom to each team to make the most sensible choice within the technical regulations and available budget.

When the car appeared for the first time, many saw similarities between the Brazilian prototype and the Red Bull X2014, virtual prototype developed by Adrian Newey for the Gran Turismo franchise. This “similarity” is due to both cars being developed in a “no rule” environment, with great technical freedom. Besides the virtual machine, the AJR has it’s similarities to other machines conceived to run at Pikes Peak, Rhys Millen’s RMR PM580 Hyundai and Cody Loveland’s Enviate Hypercar.

Red Bull X2014 Standard

RMR PM580 Jyundai Pikes Peak

Lovefab Enviate

Metalmoro JLM AJR

Part 1 – Aerodynamics

Starting by the front, the AJR is a mix of single seater and prototype concepts, with a nose reminding some F1 cars from the early 90’s (1), working with a splitter (2) and two elements that turn part of the splitter into a dual element wing (3). Fenders (4) look to have been designed to encourage air flow to contour them instead to direct them over the fenders, Front suspension is a double wishbone with onboard dampers, very similar to a single seater.

Still at the front of the car, there are dive planes (5) and louvers (6), both solutions aimed to increase front downforce. At the rear, the same louver solution is found, also to reduce the lift generated by the wheel spin.

Going to the side of the car, the profile is lean, an indication of a relatively low Cd. The radiators air intake (7) are integrated to the side of the cockpit, and the same can be said of the rear brakes cooling intake (8). The dorsal fin (9), is very different of those found in Le Mans prototypes, as in the AJR it does not blend to the rear wing. My guess is that this design is a balance between side force and skin drag.

From the rear, the wing (10) is a dual element type, allowing a more effective component at angles of attack that are more aggressive. Support is the omnipresent swan neck (11), a solution born from the LMP cars to improve rear wing efficiency. Endplates (12) have some horizontal louvers right above the airfoil plane, probably to optimize drag induced by the wing tip vortex, while two vertical slats at the base of the endplates seem to exert a similar function.

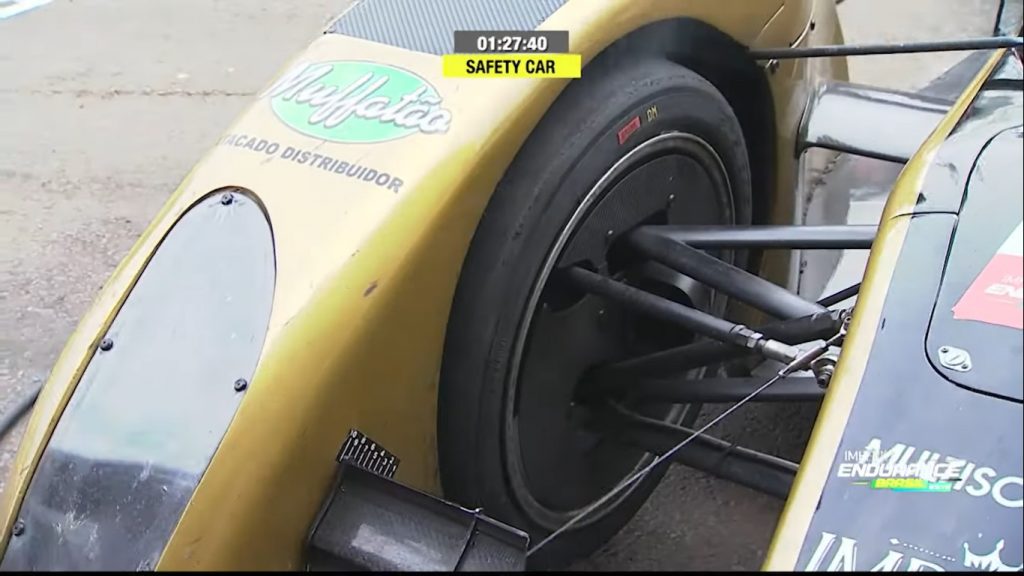

From this angle, we can see the two tunnels (13) under the AJR floor, ending with a considerably large diffuser, similar to what one would expect from a time attack machine. It is interesting to note a strake to separate flows with different energy levels, thus optimizing extraction. There are also four strakes (14) on each rear fender, that from this angle seem to direct the flow to the rear wing lower plane.

Part 2 – Powertrain

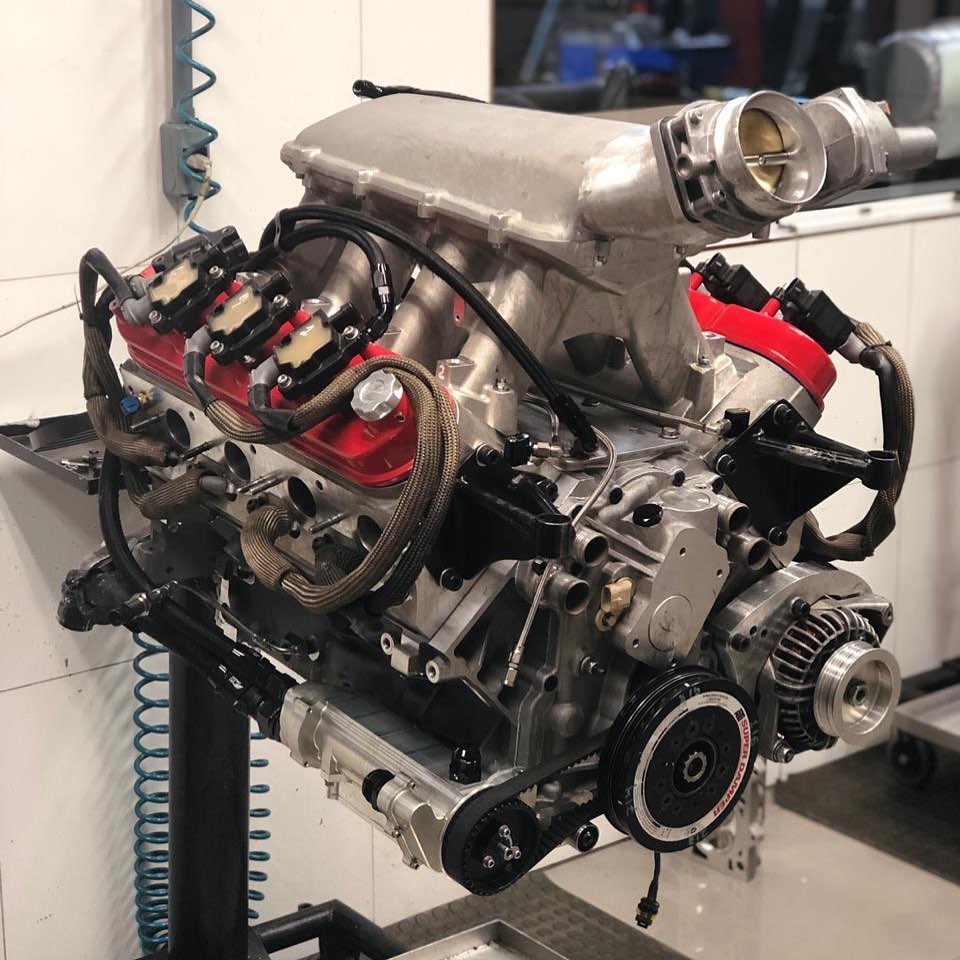

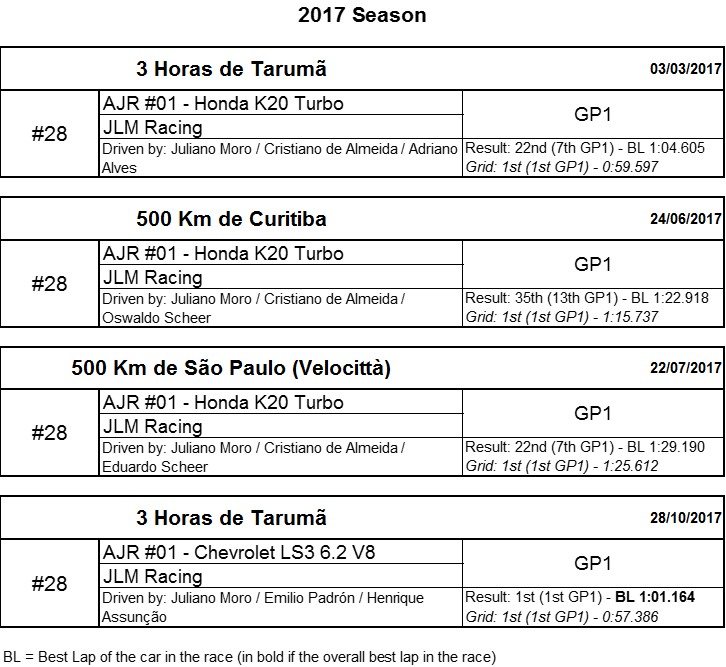

Right at launch the AJR potential became clear, taking the overall pole-position in the first race it took part, fact to be repeated in the other two races from the 2017 season. The first car built had a Honda K20 Turbo engine that, despite being powerful and light, had reliability issues.

Debuting at 2017 season finale, a new powertrain package was chosen, using a Chevrolet V8 LS3 equal to that used in Brazilian Stock Cars, however without the Stock Car’s mandatory restriction on throttle body angle. This combination proved to bring some needed reliability, resulting in the first overall win for the car at the 3 Hours of Tarumã. This package became the standard for the AJR, resulting in 7 pole positions at the 7 rounds of the 2018 Endurance Brasil championship, besides the pole position at the 500 Km of São Paulo. However, reliability still proved to be the Achilles heel of the car, with only two overall wins at Tarumã and Santa Cruz do Sul. Anyway, the car proved its value, and by the end of 2018 5 cars had been built.

Transmission wise, the same Xtrac P1152 transaxle, the same used on the LMP3 cars and a carry-over from Metalmoro’s former car, the MR18. This transaxle can handle up to 540 N.m of torque and pneumatic actuated paddle shifts.

2019 Season

In 2019 8 AJRs had been built, 4 racing with JLM “works” team and another 4 by privateers, with different engines in use, proofing AJR’s versatility.

1st Round – 4 Hours of Curitiba

In the season opener, 6 AJRs were raced: four by JLM Racing (#11, #88, #113 and #175) and two from privateers, #5 from MC Tubarão and #65 from NC Racing. All cars used Chevrolet LS3 engines but the #11, which used a Honda K24 Turbo.

Aerodynamically the cars showed little difference, to highlight the choice between louvers and fully opened BHHs (#65 car kept the original louvers while the others opted for fully opened wheel arches).

Other small difference is the additional air intake right after the rear wheels, present only in the #5 car. From the position, it looks to aim at directing extra cooling to the rear brakes.

Looking at the cars profile, there is another detail: the dorsal fin on cars #11, #65, #88 and #113 is different from the original configuration, with a more pointy rear end, if compared to the blunt configuration kept by cars #5 and #175.

2nd Round – 4 Hours of Goiânia

Looking at the cars profile, there is another detailThe arrival of the Ginetta G57 prototype not only meant a new strong contender to the AJR, but also showed one of the points the Brazilian prototype was lacking: straight-line speed. According to some sources, this deficit was around 15 kph (9 mph) across the longer straights, and was mainly due the AJR V8’s running with reduced power (~450 HP in race trim vs 550 HP in qualifying trim) to keep reliability, while the British prototype kept the full 580 HP from its V8 even in race mode.

To address this deficit, a DRS similar to F1 and DTM debuted at round 2, first only equipping cars #88 and #113. This system is said to provide 8 kph of top speed at Santa Cruz do Sul (at Goiânia the system is believed to provide up to 12 kph due to the longer main straight).

[EDIT: jun/02/2020]: During 2019, the AJR DRS has gone through a continuous improvement process. Initially, the pneumatic actuator was a single-action type, with only one retunr spring (image below), however in certain conditions the response time was far from optimum, with the system taking too long to close the wing.

Starting from the seventh round, a configuration with a second spring linking the actuator arm to the actuator support, as seen on the images below.

According to sources, even the second spring did not achieve the desired performance, driving the JLM teams to change the actuator from single action to double action, starting from the 8th round of the 2019 season, as can be seen below:

Still about the DRS, the system actuation is pneumatic, employing a compressor and air reservoir similar to those used by the paddle shift system of the Xtrac transaxle, with a solenoid valve controlling the system activation.

For the other cars, the aerodynamic package was basically the same as Curitiba, the only difference being the #65 car that raced without the front dive planes, perhaps an indication of a different aero set up.

3rd Round – 3 Hours of Santa Cruz do Sul

Third round was a remark to the AJR history, being the first time all 8 AJRs built raced (and the only such occasion until now), even if the #11 effectively had not race after it caught fire during the training sessions. Besides that, this race was the debut of a major mechanical update to car #65, as the engine tuned by Motorcar Racing was upgraded, with an increase in displacement from 6.2 to 6.9 liters, also with an aluminum ram-type intake manifold. The result is probably the more powerful engine in the field, with 650 HP available for the drivers (although, in the paddock, word says this engine is reaching 800 HP, however it is not clear if this is a number at the flywheel, while 650 HP would be at wheel, or if this is the max power in qualifying mode).

Also at the third round, cars #88 and #113 received yet another update, in the form of a winglet at the rear end of the side pods, right below the brake cooling intake. This part seems to add extra downforce without impact the aero balance of the car, as its position is near the centerline, while also not making a huge increase in drag.

Back to the louver thing, some news at this round: car #88 reverted to using louvers at the front, while cars #46 and #113 debuted a bolt on cover, as shown below.

[EDIT: jun/02/2020]: During a talk on the social medias the explanation for the different BHHs solutions was provided. The original louver solution employed fins with an aerodynamic profile, produced via 3D printing. However, teams started to have issues were these “fins” would break up during track time. Being an expensive component and without a easy fix to be implemented, many teams choose instead to run the BHHs without any cover. The fully covered arch wheel is a solution devised as an alternative to the original louvers.

Among the newcomers (cars #46 and #80), the first ran without the secondary element to the front wing, possibly to reduce drag as this was the least powerful car in the grid, with it’s Audi Turbo engine believed to produce around 400 HP.

Another curiosity from this race is the different air scoop shapes that became clear with all cars running together. At least three different designs can be identified, although this cannot be directly linked to the engine choice, as car #113 (one of the V8s) uses a somewhat smaller intake, while #80 uses an even smaller one, and with a more square contour.

Below an image of car #80, with a better view of the air scoop.

The great novelty of car #80, however, is the Nissan VQ35 V6 engine, a first among the AJRs, aimed at placing the car at a lower weight limit within the regulations.

4th Round – 3 Hours of Velopark

Fourth round saw the 4 works cars receive a new front wing, increasing from two to four elements, hence allowing a more aggressive angle of attack and consequently more downforce to be generated, also allowing greater margin to meddle with aero balance.

MC Tubarão’s #5 also received some updates, with the “pointy” dorsal fin and fully enclosed BHHs at the front fenders.

Among the others, all cars but #80 received the front BHH cover, and car #80 received the DRS system (info has that the found the V6 engine to be lacking in power, and hence speed to the others).

Mechanically, #88 car changed engine tuner, migrating from Giaffone Racing to Motorcar Racing. Engine changes are hard to spot since most things happen inside the engine, however the engine prepared by Rafael Cardoso caught attention with the 8 trumpets replacing the original polyamide manifold used by Giaffone Racing. Power numbers were not revealed, but should be over 600 HP.

5th Round – 4 Hours of Interlagos

At Interlagos, cars #5 and #65 received the same updates as the works cars, except the side pod winglet (meaning they received the DRS system + new front wing + front BHH covers). Among the JLM cars, #113 received F1 style brake ducts, replacing the grassroots system of flexible pipes directing air to the front brakes.

Another new is that car #88 changed hands to Vicente Orige, receiving a new livery and the number 43.

Car #5 presented a second dive plane, something not seen on other cars.

This race also marked the return of AJR #11, after the fire that nearly destroyed the car in Santa Cruz do Sul, already equipped with DRS, new front wind and side pod winglet, but curiously with the blunt edge shark fin.

Being a partially nocturnal race, cars #5, #11 and #65 spotted additional LED lights assembled on the front nose.

6th Round – 3 Hours of Goiânia

Goiânia saw few updates being implemented, with a highlight to car #5, that brought a second inlet on the rear side pods, probably to improve cooling at the rear brakes, on a track were lots of cars suffered from brake failures.

Besides that, the remaining works cars received the F1 style brake ducts.

7th Round – 3 Hours of Santa Cruz do Sul

Santa Cruz do Sul saw again few aero updates introduced, the only one being the car #175 finally receiving the pointy edge shark fin.

Mechanically, car #11 received a LS3 engine, a surrender to what became almost a standard among the AJR prototypes. Interesting to note that this is the Evo version from Giaffone Racing, which received some updates to bring power to around 600 HP. What denounces this update is the new Intake Manifold, a LSXR 102 mm from FAST (Fuel Air Spark Technology). This updated engine is believed to had been already implemented on cars #113 and #175 from quite some time.

Besides being an indicator of the engine update, the new intake manifold also gives some insight to the philosophy behind this evolution, as cars #65 and #43 have intake manifolds clearly oriented to provide maximum power, even at the expense of some low-end torque. The LSXR manifold, on the other hand, has the characteristic of providing modest gains, albeit distributed throughout the entire power band, as a test run by a href=”https://www.enginelabs.com/engine-tech/intake-manifolds/dyno-testing-four-popular-ls3-bolt-on-intake-manifolds/”>Engine Labs demonstrated.

8th Round – 6 Hours of Curitiba

Closing the 2019 season, the 6 Hours of Curitiba counted with the reborn of the AJR #80, from Alexandre Finardi. This car was originally thought to use a naturally aspirated Nissan V6, to run in a lower minimum weight requirement. However, even weighting less the car could not keep up with the pace of the V8 cars, mainly due to lower straight-line speeds. The team even tried to run a DRS to address this issue, but since all cars would eventually receive this update it was a dead end. After a fire nearly destroyed the car ao Velopark, the reborn car received another Nissan V6, this time equipped with a supercharger from Vortech Superchargers, with max power believed to be around 600 HP, and the benefit of a good amount of low end torque. In this configuration, car #80 managed even to fight for the lead at Curitiba, before a mechanical woe took the car out of the race.

Regarding the aero, the Nissan powered car has DRS, updated front wing and shark fin, however without parts like the brake ducts, side pod winglet and front BHH covers. Unique to this car is a second air intake right below the rear brake ducts, present only at the right side pod.

Fire incidents

While 2019 was the year when the AJR truly established itself in the Brazilian tracks, with 6 overall wins and all pole-positions in 8 rounds, the season was also marked by fire incidents, some of large proportion.

The first fire incident happened during the warm-up to the season opener in Curitiba, when an oil line got loose starting a fire in the car of Pedro Queirolo and David Muffato. The result was a burnt engine cover, but no additional damage, with the car even making to the starting grid.

Second incident was at the third round, this time in the AJR #11 of Emílio Padrón. The car was being driven by Marcelo Vianna in the free practices, and this time the fire was of larger dimensions, resulting in the car retirement from the Santa Cruz do Sul race and the car missing the following round to be rebuild.

The worst, however, was still to come. During the race at the Velopark the AJR #80 from Power Imports Racing Team caught fire on track, while driven by Rafael Suzuki.

This was a larger fire, magnified by the poor response from the fire fighting team, that not only was slow to respond, but also had trouble operating the fire extinguishers. The result was a pratically destroyed car, that would only be rebuilt by season finale at Curitiba.

Thankfully, none of these accidents resulted in injuries to the drivers nor anyone on track, resulting only in material damage. However these incidents did not pass by the JLM team. First, a antiflame coating was added to the inner part of the engine cover, to reduce the flamability and retard flame propagation.

Additionally to the mandatory fire extinguisher system in the car, the AJRs started to employ a passive fire extinguishing system, the Fire Extinguishing Ball, assembled on the inner part of the engine cover (red item in the previous image). In the video below you can see the gadget on action:

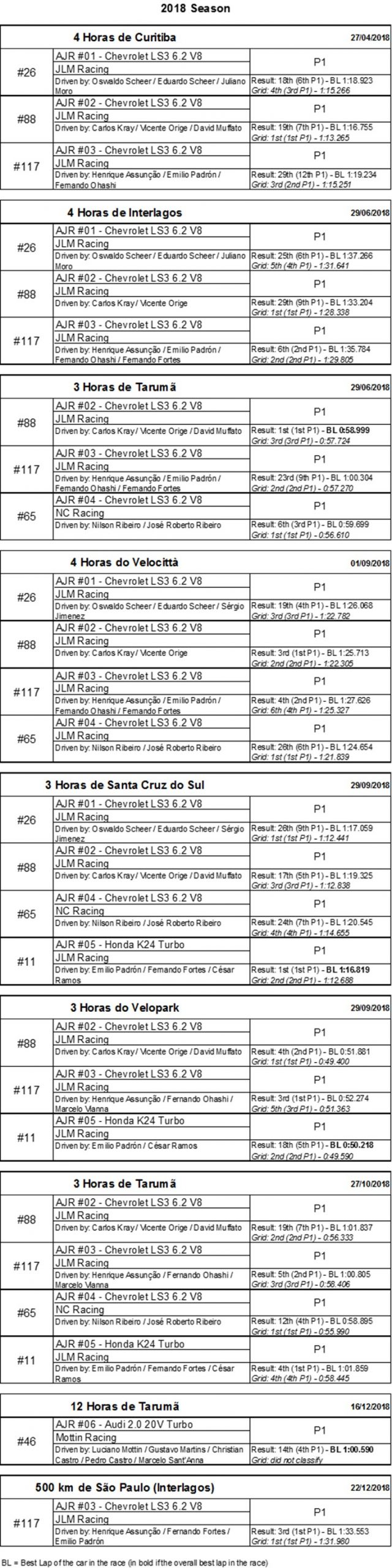

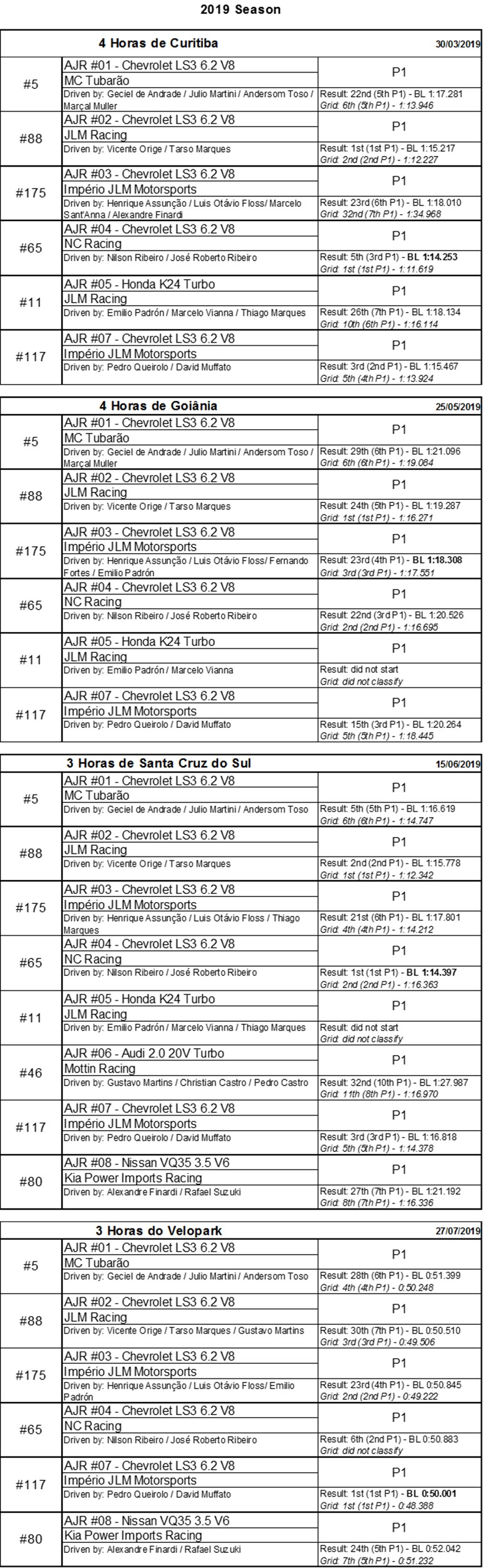

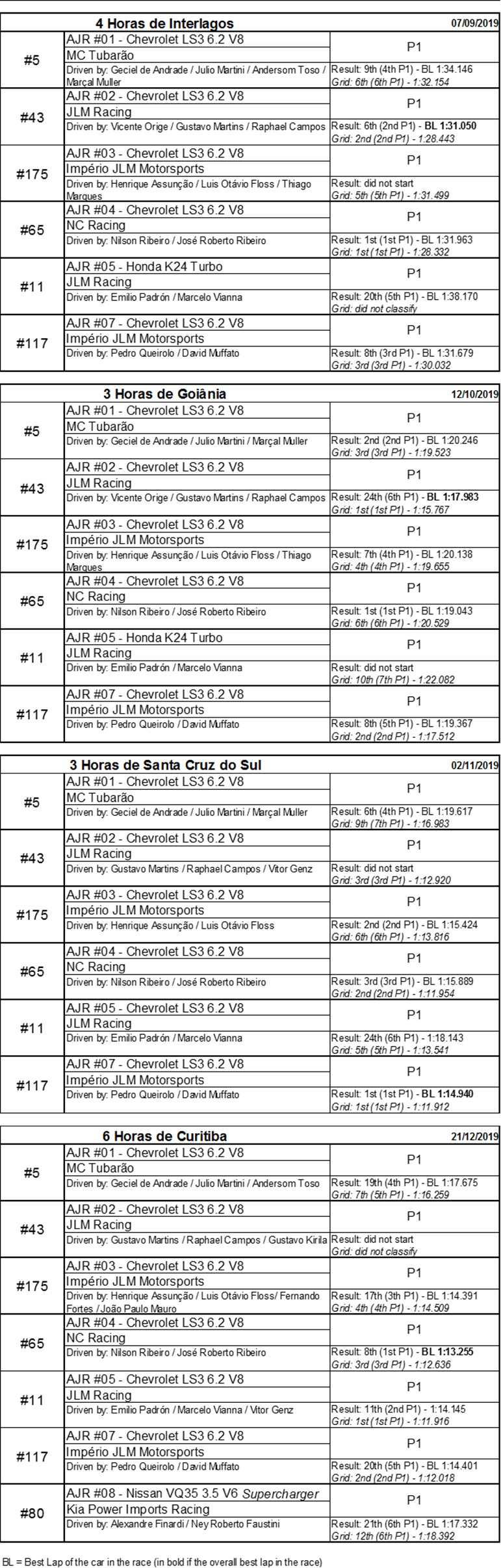

Results

Below you can find a compilation of the results the AJR obtained in Brazil so far:

You may also be interested in:

Protótipos do Endurance Brasil: MCR Grand-Am

Protótipos do Endurance Brasil: Sigma P1

Sources:

JLM Racing AJR. Available at: http://www.metalmoro.com.br/novosite/portfolio_page/jlm-racing-ajr/

Dynamic Flow Solutions. Available at: http://www.dynamic-flow.co.uk/ .

The Metalmoro JLM AJR. Available at: http://www.dailysportscar.com/2017/04/21/the-metalmoro-jlm-ajr.html

Metalmoro JLM AJR Takes First Win. Available at: http://www.dailysportscar.com/2017/11/23/metalmoro-jlm-ajr-takes-first-win.html

Giaffone Racing. Available at: https://www.facebook.com/giaffoneracing/

P1152 Longitudinal Sportscar Transaxle. Available at: https://www.xtrac.com/product/p1152-longitudinal-sportscar-transaxle/

Novidades. Available at: https://www.ncracing.com.br/noticias/

Ficha Técnina do AJR #65. Available at: https://www.ncracing.com.br/ficha-tecnica-do-ajr-65/

Dyno Testing Four Popular LS3 Bolt-On Intake Manifolds. Available at: https://www.enginelabs.com/engine-tech/intake-manifolds/dyno-testing-four-popular-ls3-bolt-on-intake-manifolds/

Images:

[1]: Source: JLM Racing AJR. Available at: http://www.metalmoro.com.br/novosite/portfolio_page/jlm-racing-ajr/

[2]: Source: The Metalmoro JLM AJR. Available at: http://www.dailysportscar.com/2017/04/21/the-metalmoro-jlm-ajr.html

[3]: Source: Giaffone Racing. Available at: https://www.facebook.com/giaffoneracing/

[4]: Source: P1152 Longitudinal Sportscar Transaxle. Available at: https://www.xtrac.com/product/p1152-longitudinal-sportscar-transaxle/

[5]: Source: Galeria de Imagens. Available at: http://www.imperioendurancebrasil.com/imagens.html

[6]: Source: Emilio Padrón. Available at : https://www.facebook.com/emiliopadrondriver/

[7]: Source: MC Tubarão. Available at: https://www.facebook.com/mctubarao/

[8]: Source: Motorcar Racing. Available at: https://www.facebook.com/motorcarracing/

[9]: Retirado de: Ajr Oitenta. Available at: https://www.facebook.com/bira.jacobsen

[10]: Source: LSXR 102 mm. Available at: https://www.fuelairspark.com/intake-manifolds/lsxr-102mm.html

[11]: Source: Marcelo Vianna: calma e frieza para escapar de um incêndio. Available at: https://globoesporte.globo.com/blogs/voando-baixo/post/2019/06/20/marcelo-vianna-calma-e-frieza-para-escapar-de-um-incendio.ghtml